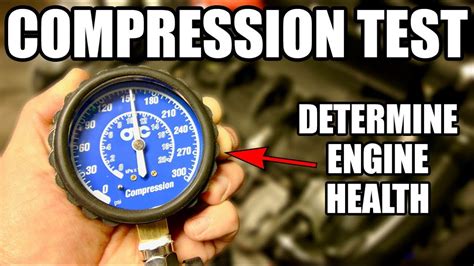

compression test cilynder|cylinder compression test procedure : agency Doing a compression test, is a good way to measure the condition of, the rings, cylinders, and valves. So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance. Share. r/Thai_freires_Putinha: vídeos e fotos da gostosa da Thai freires.

{plog:ftitle_list}

20 de out. de 2022 · Nossos resultados são atualizados em tempo real, oferecendo uma forma conveniente e confiável de verificar seus bilhetes. Não deixe de acompanhar as .

An engine compression test measures the pressure within the engine cylinders during the compression stroke. This pressure indicates how effectively the engine compresses the air-fuel mixture, which is essential for .How to check engine cylinder compression using a compression tester. This article explains how to test engine compression to find faults with head .

Dec 18, 2018

Portable dried fruits and vegetables Moisture Meter distribute

Doing a compression test, is a good way to measure the condition of, the rings, cylinders, and valves. So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance.At its most basic, a compression test will tell you whether or not an engine cylinder has good compression. The second stroke of a four-stroke internal combustion engine is the compressing stroke. This is when the piston . The standard test methods for concrete cylinder compression are delineated primarily by ASTM C39/C39M – Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. This method .In Example 1, cylinder #1 has a snap test reading that is much lower than the other cylinders. If a snap reading is low (much less than 80% cranking compression), look for air intake problems such as severe carbon deposits on intake valves, worn cam lobe,worn valve guides and springs, rocker or push rod problems, or "shutter valve" miss-positioned in the runners of a variable .

Regularly scheduled maintenance for the cylinders consists of compression checks and cylinder removal and replacement, and valve check. 1. Perform compression checks at 100 hours of engine operation and annual inspection . Perform the compression test as soon as possible after engine shutdown to provide uniform lubrication of the cylinder .

test cylinder compression without tester

Concrete Compressive Strength Testing. Compression testing of concrete cylinders is the final step in this process and is performed following the standard test method ASTM C39/AASHTO T 22. The prepared concrete test cylinders are placed in a concrete compression machine and loaded axially at controlled rates until failure.Neoprene Pads flow during compression to fill irregularities in the cylinder ends and assure load uniformity. Pads are economical and can be reused for up to 100 tests. 4in and 6in pads meet the latest ASTM C1231 and AASHTO T 22 specifications. . Rings and pads are positioned at each end of the concrete test cylinder to distribute compressive .

Materials Testing System. ASTM C39 has updated the test control methods when crushing concrete. The speed of your testing is dictated by the control type, and it is important to make sure you are testing quickly and efficiently. The standard states that displacement-controlled devices test at different rates depending on the size of the specimens. Compression Testing and What You Can Learn From It - EricTheCarGuyHere is a video on performing a compression test on an engine to assess it's mechanical con.

The MegaForce Concrete Testing System works with compression machines that operate up to 69 MPa or 10,000psi. Depending on the indicator chosen with the system, automated compressive strength test reports are generated, saving time as well as costs required to manually generate reports while decreasing the chance of errors.

8-in-1 Tool Kit:The KOOPOOL Cylinder Compression Tester Kit includes: 1 compression gauge, 1 straight rubber cone end adapter, 1 curved rubber cone end adapter, 4 adapters with metric male fittings and O-rings (M10, M12, M14, M18), 1 16.3-inch extension hose, and 1 fabric pouch; Durable Constructio:The KOOPOOL Cylinder Compression TesterCompression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .

CASE 1: One or more cylinders had a much lower compression value than the others. Up to a certain range, this could be normal. To further interpret these test results go to: Interpreting The Compression Test Results. CASE 2: All six cylinders had almost no compression or 0 PSI compression. This low or zero compression on all cylinders will .

Engine cylinder leak down testing allows mechanics to pinpoint the cause of compression loss in a specific cylinder. A cylinder leak down test gives mechanics an inside look at the internal integrity of any engine, finding many issues that would otherwise take some major disassembly to pin point. Testing the engine compression on your Chevrolet or GMC 4.8L, 5.0L, or 6.0L engine is not hard to do. A compression test will help you to determine the health of your engine by measuring the pressure of the air that . By measuring the compression pressure within each cylinder, compression testing provides valuable insights into the engine’s overall condition and helps uncover any underlying problems that may affect its performance. Let’s delve into the two main purposes of compression testing: assessing engine performance and identifying cylinder issues. .

ASTM C39 Procedure. 1. Bring the cylinders out of the moisture room, keeping them covered with wet burlap to keep them moist. Check the cylinders over for defects (holes, cracks, crumbliness) as you set them on the table, use your straight edge and nail to check for . A car's engine needs cylinder compression to run correctly. . Compression Test Service Costs. When having a compression test done by a repair shop the costs will vary depending on how many cylinders your car's engine has and how difficult the sparkplugs are to remove. Most shops will charge about .00 for a 4 cylinder and about 0.00 (US .

Hay Moisture Meter distribute

GreatNeck Compression Test Gauge - 37138. Part #: 37138 Line: GRT. Limited Lifetime Warranty. Links. CONNECT with O'Reilly. Professional Parts People ® Explore Jobs. CONNECT with O .Yes, a dead cylinder can be fixed by checking and rectifying any defective component that falls among some of the reasons that result in a dead cylinder; in order to fix a dead cylinder, you will have to diagnose the cylinder by using a compression gauge to test whether there are any cylinders with no compression.Compression testing: Calculation methods, advantages, applications in various materials, metals, polymers, ceramics, and composites. Home; Company; Products. Mechanical testing; . and the test specimens can often be simple shapes like cylinders or cubes. In conclusion, compression testing is a powerful tool that provides essential insights . starter motor and measure the compression. Compression Pressure: Above 930 kPa (9.5 kgf/cm , 135 psi) 7. Measure the compression on the remaining cylinders. Maximum Variation: Within 200 kPa (2.0 kgf/cm , 28 psi) 8. If the compression is not within specifications, check the following items, then remeasure the compression. • Damaged or worn .

Fiada 9 Pieces Automotive Compression Tester Kit and Spark Plug Tester, Universal Car and Motorcycle Engine Testing Tools for Cylinder Pressure Gauge (Red) 4.5 out of 5 stars 1,245 1 offer from 99 $ 21 99 This video shows how the compression strength of concrete (f'c) is measured using a standard cylinder (per ASTM C39). Thank you to my dad for creating the mu.

most accurate compression tester

how to check cylinder compression

If a compression test is below the manufacturer's specifications, there's an internal engine issue. How It Works. Pricing. . Step 15: Remove the compression gauge from that cylinder by unthreading it by hand. Step 16: Repeat steps 11-15 until all of the cylinders have been checked. Make sure the readings are recorded. If all cylinders test equally low, a valve timing problem or excessively worn piston rings are indicated. Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The . Equipment for Concrete Cylinder Compression Test. The equipment used in concrete cylinder tests are: Compression testing machine. Cylinder mold of 150 mL diameter and 300 mL height or 100 x 200 mL. Weighing balance. Concrete mix preparation and handling are crucial for accurate test results. Issues such as incorrect mix proportions, poor .

Digital Waste Paper Moisturizer distribute

engine compression tester advance auto

Ágatha Ludovino, 21, foi a primeira atriz a expor Binho publicamente. Em um vídeo publicado no YouTube, em 2019, ela o acusava de abuso . Ver mais

compression test cilynder|cylinder compression test procedure